Guide to Outdoor Staircases: Durability, Design Rules, and UK Compliance

Outdoor staircases are one of the most important design elements of a home. They provide convenient access to upper floors and ensure safety. They also greatly impact the aesthetics of your home's exterior and garden. A properly designed and constructed staircase, especially one made from durable materials like steel, is an important investment. It will help improve home safety and prevent costly repairs in the future.

In this guide, you can find a comprehensive overview of important factors for any UK homeowner: installation costs, the lifespan of materials, the stringent UK Building Regulations (Part K), and key design standards.

Understanding the Cost of External Stairs

The financial investment required for an outdoor staircase depends on the materials, size, complexity of the design, and the required foundation. A simple garden staircase made of brick or stone can cost an average of £815, while a complete staircase installation that meets the requirements typically costs between £1,200 and £6,000. Bespoke steel staircases are often more expensive than prefabricated options available at home improvement stores because they require more work, but on the other hand, custom-made stairs are guaranteed to fit your needs and last longer.

Here is a typical cost breakdown for UK installations:

| Type of Stair | Average Cost (UK) | Notes |

|---|---|---|

| Garden stone/brick steps | £815 | Low-rise steps, quicker installation |

| Standard straight design (Steel/Timber) | £1,500 – £4,000 | Cost dependent on basic materials |

| Prefabricated galvanised steel | £650+ | Cost-effective, weather-resistant base |

| Bespoke or Spiral Steel Design | £4,000 – £6,000+ | Higher fabrication costs, ideal for tight spaces |

A spiral steel staircase is a great space saver, but it also requires complex fabrication and welding processes, which increases its cost.

Furthermore, custom elements such as stainless steel finishes, special coatings that protect against weathering, or complex landings increase the overall budget.

Always look for great deals from metal fabrication specialists in Hampshire and Surrey to ensure you get a staircase at a fair price.

The Unmatched Durability of Steel Staircases

In terms of long-term value, steel staircases are the epitome of durability and resistance to external influences. A properly manufactured and maintained steel staircase can last 25–50 years or more. Clearly, steel staircases significantly outperform wooden or many concrete structures. This longevity can be achieved through professional manufacturing and protective treatment.

The key to longevity is the finish. Galvanized steel provides excellent corrosion protection thanks to its zinc coating. This makes galvanized staircases an excellent choice if you need to install a staircase "once and for all." Besides galvanization, there are other coating options, such as powder coating. This also provides excellent surface protection and minimizes wear on the staircase.

Also, simple regular maintenance, such as cleaning and promptly repairing visible chips, will help extend the life of any steel staircase, whether it's a straight one or a complex spiral staircase.

UK Building Regulations: Ensuring Safety and Compliance

All external staircases must strictly comply with UK Building Regulations (specifically Parts K and M). These requirements set minimum standards for safe access, effective drainage, slip resistance, and structural stability. Designers must provide robust safety railings (balustrades or handrails) and a solid foundation for any change in height greater than 600 mm. Ignoring these regulations is one of the most serious and costly mistakes in external design.

Key Design Principles for Comfort and Functionality

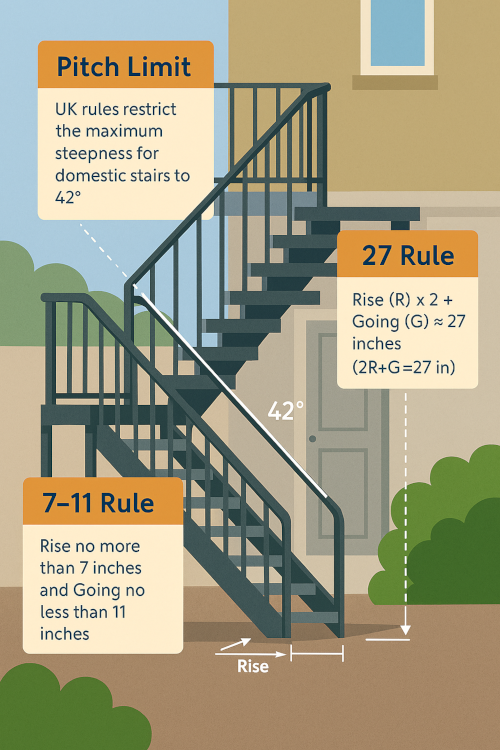

In addition to the minimum legal requirements, steel staircase manufacturers must adhere to established industry regulations. This ensures that the staircase meets the requirements and is comfortable to use. These regulations determine the optimal ratio between the rise (vertical height) and tread depth (horizontal depth) of each step.

These sizing formulas are often used to calculate the dimensions of ladders and their usability. However, it's always important to consider local requirements and building codes. British regulations specify specific parameters, such as a step height of 150–220 mm, a maximum of 16 steps per flight, and a minimum width of 750 mm for residential applications. These parameters were developed to ensure that ladders are comfortable for everyone and also to reduce the risk of falls.

The Second Staircase Rule

In large construction projects, it's crucial to consider the second stairway rule. This is one of the fundamental fire safety regulations that applies to all new residential buildings. According to this rule, any residential building taller than 18 meters must have a second evacuation stairway. This rule comes into effect in September 2026. It was developed to improve evacuation safety in high-rise residential buildings.

Common Pitfalls and Planning Permissions

When ordering custom metal staircases, it's crucial to consider potential design errors. The most common mistakes include:

ignoring building codes;

incorrectly measuring risers and treads;

poor lighting;

choosing purely decorative elements instead of functional safety features, such as properly designed handrails.

It's also important to consider the disadvantages of metal. Despite their durability, metal staircases can rust if improperly treated. They can also be noisier than wood. Furthermore, custom steel staircases can be more expensive than staircases made from other materials.

Do I Need Planning Permission?

The requirement for planning permission is often property-specific. For many standard domestic properties, an external staircase may fall under Permitted Development Rights. However, if your property is a Listed Building, if the design constitutes a major, visible alteration, or if you are in a protected area, permission will be required. Always consult your local authority to confirm the legal requirements before starting the fabrication process, especially for structural steel staircases.

Conclusion

Outdoor staircases require detailed design. It's best to outsource fabrication and installation to experienced metalworking specialists like Oakhanger Metalworks. By carefully calculating costs, purchasing durable materials like galvanized steel, and adhering to building codes, you'll be able to create a staircase that complies with regulations, is durable, and aesthetically pleasing.

A properly designed staircase will undoubtedly be a stunning addition to any building.